the

G6 / G6 MT 5-axis machining / machining-turning centre

with rear pallet changer options to maximize work area access / spindle up-time / FMS integration

with rear pallet changer options to maximize work area access / spindle up-time / FMS integration

Features:

- High-performance built-in spindle

- Table moved by swiveling-rotary axes

- Perfect U-shape closed-gantry design

- Linear scales on all guideways

- For G6 MT - Mechanical and laser-type tool measurement system

- For G6 MT - Integrated balancing system with additional screen monitor (Option)

- For G8 MT - Accurate in-process tool measurement in length, radius, and shape

Included AXILE Technologies:

- SMT Smart Machining Technology

- ART Intelligent Monitoring System

With a rotary table diameter of 600mm the AXILE G6 is a compact vertical machining centre designed for agile, smart machining of smaller workpieces requiring complex geometries and intricate features. This highly versatile VMC delivers full 5-axis CNC machining with the built-in spindle moving along the X/Y/Z-axis and the table moving in rotary C-axis and swiveling A-axis.

The AXILE G6’s perfect balance of speed and precision makes it the perfect option for job shops and production lines seeking an upgrade in machining capabilities, delivering high removal rates, excellent surface finishes and maximum production efficiency.

In addition to the high-performance AXILE G6 model AXILE also offers the AXILE G6 MT which combines both milling and turning in one machine greatly increasing operational flexibility. By reducing set-up times and potential clamping errors the AXILE G6 MT can efficiently machine a wider variety of parts including cylindrical components.

The AXILE G6’s perfect balance of speed and precision makes it the perfect option for job shops and production lines seeking an upgrade in machining capabilities, delivering high removal rates, excellent surface finishes and maximum production efficiency.

In addition to the high-performance AXILE G6 model AXILE also offers the AXILE G6 MT which combines both milling and turning in one machine greatly increasing operational flexibility. By reducing set-up times and potential clamping errors the AXILE G6 MT can efficiently machine a wider variety of parts including cylindrical components.

G6 / G6 MT Specifications:

- Rotary table diameter: G6 - 600mm; G6 MT - 500mm

- Maximum table load: G6 - 600kg; G6 MT - 350kg (Turning), 500kg (Milling)

- Maximum X, Y, Z axis travel: 650mm, 850mm, 500mm

- Maximum spindle speed: 20,000 rpm (standard) or 15,000 rpm (option) or 36,000 rpm (option)

Standard Technology

Spindle:

Cooling System:

Coolant Wash-Down and Filtration:

Equipment and Component:

Automatic Tool Changer:

Measuring System:

Optional Technology

Equipment and Components:

Automatic Tool Changer:

Coolant Wash-Down and Filtration:

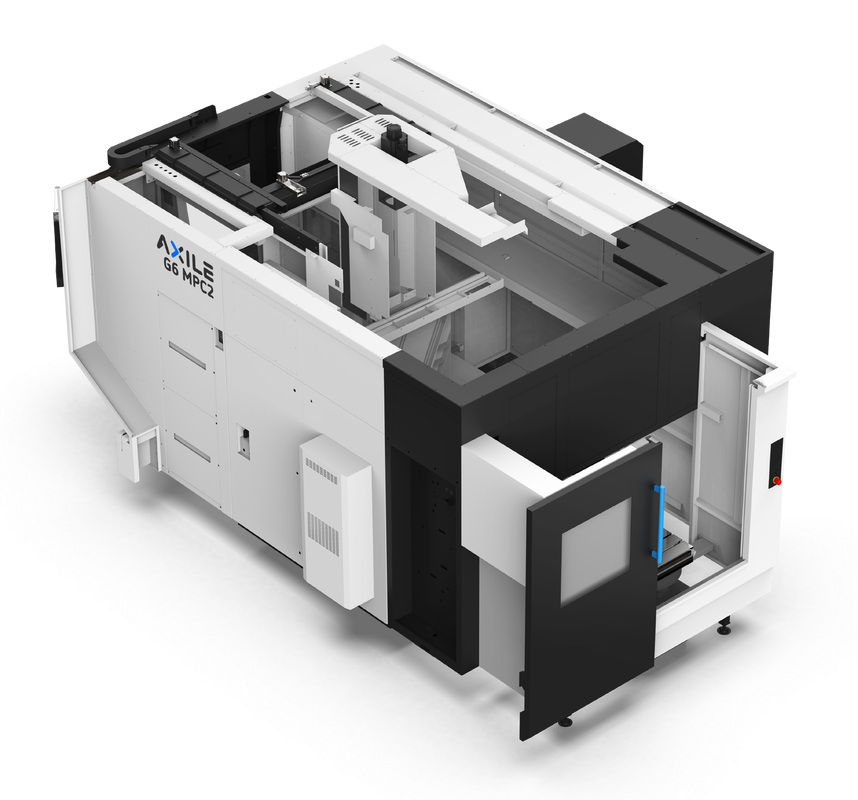

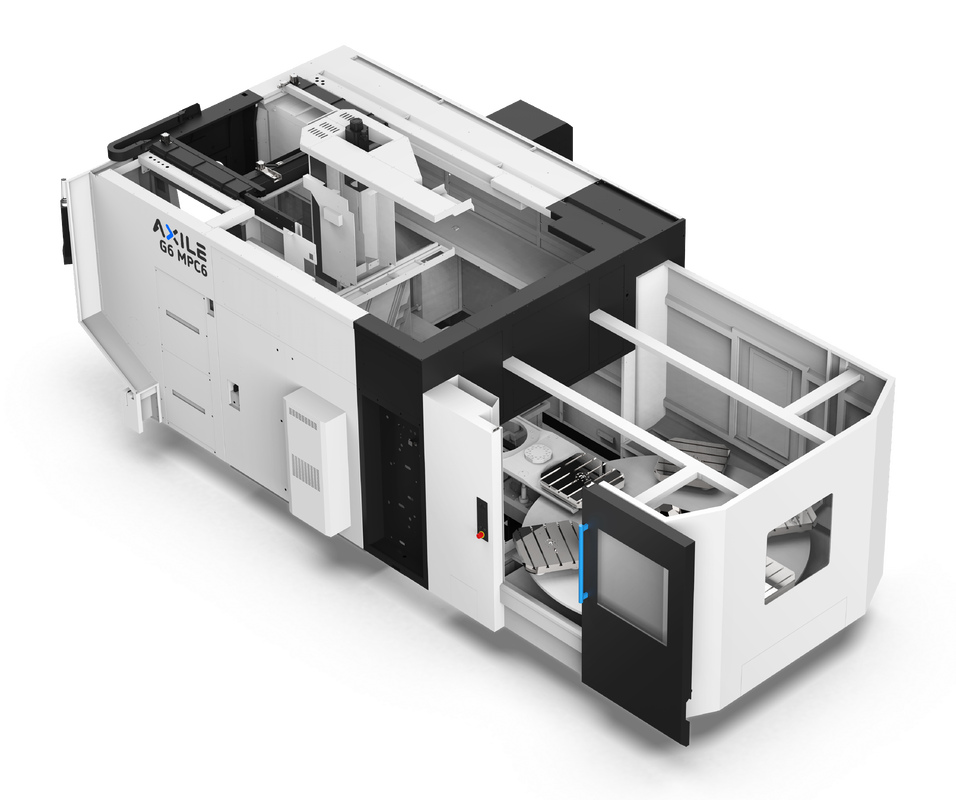

G6 MPC automatic pallet changer:

Available with two or six pallets AXILE’s automated G6 Motorized Pallet Changer (MPC) exchanges raw workpieces and finished parts via a loading bay at the back side of the machine. Operators can load raw workpieces and inspect / unload finished parts while machining continues in the vertical machining center 24/7, dramatically increasing operational efficiency.

Freedom and flexibility are core to the design concept as the MPC solution can be integrated after initial commissioning of the G6 machine or at a later stage when production capacity expands. And with the MPC-2 (the two-pallet solution) manufacturers can embrace a Flexible Manufacturing System (FMS) of 12, 24, or 36 pallets total by integrating one to three machines and two loading stations depending on the scale required.

With AXILE’s digitalized intelligent automation solutions, manufacturers can eliminate production bottlenecks and ramp up production.

Features:

Spindle:

- built-in transmission coolant-through spindle

Cooling System:

- air conditioner for electrical cabinet

- water chiller for table and spindle

Coolant Wash-Down and Filtration:

- 40bar coolant through spindle with high pressure coolant pump

- coolant gun

- chip conveyor (chain type)

- oil skimmer

Equipment and Component:

- workpiece probe

- laser tool setter

- smart tool panel

- auto roof for overhead crane loading/unloading

Automatic Tool Changer:

- 80 tool pockets

Measuring System:

- linear scales

- rotary scales

- specially designed mechanical and laser type tool measurement system

Optional Technology

Equipment and Components:

- automatic spin window

Automatic Tool Changer:

- from 120 to 360 tool pocket magazines

Coolant Wash-Down and Filtration:

- coolant through spindle coolant tank with paper filter and high pressure 40/70 bar coolant pump

- oil mist collector and recycling equipment

G6 MPC automatic pallet changer:

Available with two or six pallets AXILE’s automated G6 Motorized Pallet Changer (MPC) exchanges raw workpieces and finished parts via a loading bay at the back side of the machine. Operators can load raw workpieces and inspect / unload finished parts while machining continues in the vertical machining center 24/7, dramatically increasing operational efficiency.

Freedom and flexibility are core to the design concept as the MPC solution can be integrated after initial commissioning of the G6 machine or at a later stage when production capacity expands. And with the MPC-2 (the two-pallet solution) manufacturers can embrace a Flexible Manufacturing System (FMS) of 12, 24, or 36 pallets total by integrating one to three machines and two loading stations depending on the scale required.

With AXILE’s digitalized intelligent automation solutions, manufacturers can eliminate production bottlenecks and ramp up production.

Features:

- Workpiece loading/unloading done separately at back of machine

- Safe access and clear view for operators

- MPC-2 expandable to 12/24/36-pallet FMS

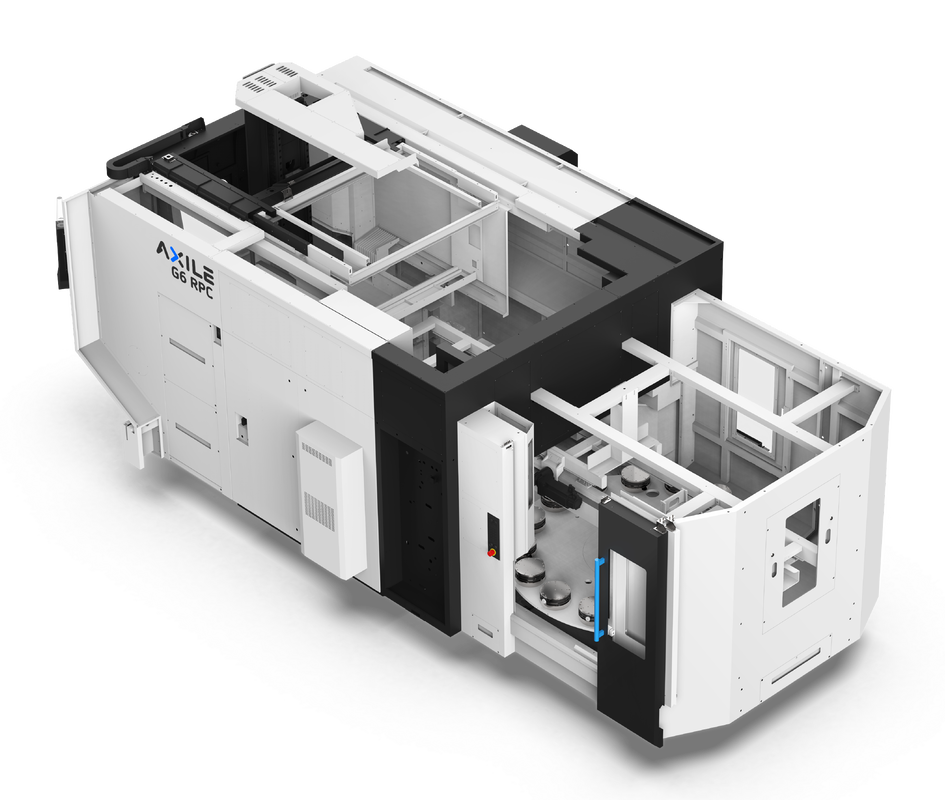

G6 RPC automatic robotic pallet changer

AXILE’s automated G6 Robotic Pallet Changer (RPC) solution features a 2-axis robot that keeps machines supplied with workpieces 24/7 from the back side of the machine. Part processing continues simultaneously within the machining centre while operators deal with workpieces at the holding area at the back, significantly raising production efficiency to boost throughput.

The G6 RPC solution caters to diverse production requirements with multiple options available based on workpiece specifications:

With AXILE’s digitalized intelligent automation solutions manufacturers can eliminate production bottlenecks and ramp up production.

Features:

AXILE’s automated G6 Robotic Pallet Changer (RPC) solution features a 2-axis robot that keeps machines supplied with workpieces 24/7 from the back side of the machine. Part processing continues simultaneously within the machining centre while operators deal with workpieces at the holding area at the back, significantly raising production efficiency to boost throughput.

The G6 RPC solution caters to diverse production requirements with multiple options available based on workpiece specifications:

- 8 pallets (maximum workpiece size 500 x 305mm - maximum workpiece weight 220 kg)

- 10 pallets (maximum workpiece size 400 x 305mm - maximum workpiece weight 220 kg)

- 16 pallets (maximum workpiece size 230 X 305mm - maximum workpiece weight 98 kg)

- 20 pallets (maximum workpiece size 160 x 250mm - maximum workpiece weight 30 kg)

With AXILE’s digitalized intelligent automation solutions manufacturers can eliminate production bottlenecks and ramp up production.

Features:

- Workpiece loading/unloading done separately at the back of the machine

- Safe access and clear view for operators

- Zero-point pallet clamping system enables rapid and safe pallet configuration

- Choice between 8, 10, 16, or 20 pallets

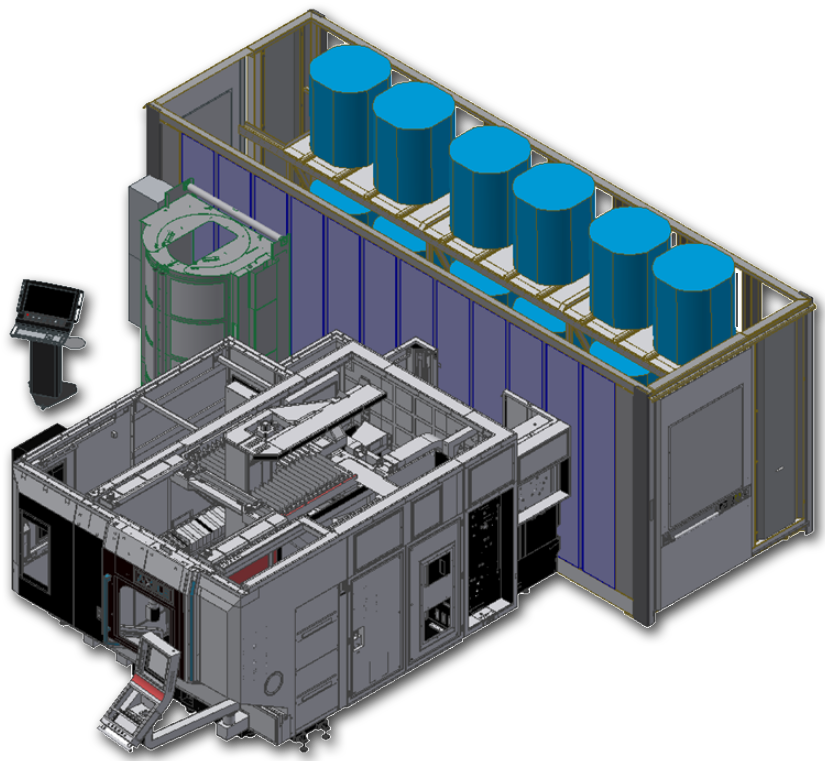

The AXILE G6 automatic pallet changer (APC) can be integrated with the ART™ System which is an intelligent monitoring system with reliability, predictability and automation functions. The G6 APC with ART™ System can help manufacturers achieve 24/7 operation without unexpected downtime and can be integrated into a flexible manufacturing system FMS):

the AXILE G6 + G6i 5-axis machining centre brochures

the Heidenhain TNC7 / Siemens One / Fanuc 30i-31i-32i model B control brochures